Produce hydrogen from methanol(first generation)

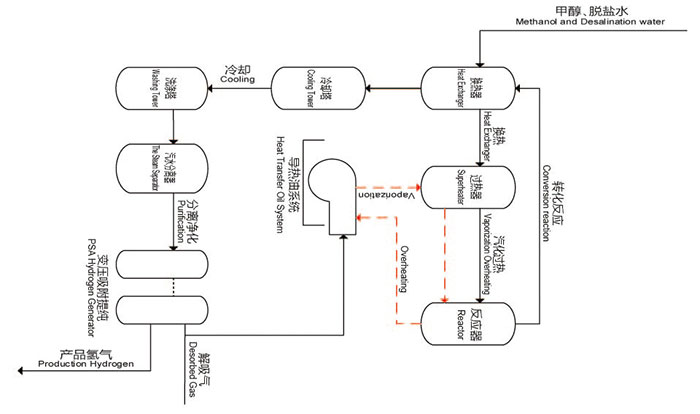

Working Principle

Methanol and water vapor in the temperature and pressure conditions,through the catalyst cracking reaction and shift reaction of carbon monoxide,to produce hydrogen and carbon dioxide.This is a multi-component,multi-catalytic reaction system,after the pressure swing adsorption process to obtain pure hydrogen.

Gas generating composition of methanol reforming hydrogen

H2:75%

CO2:24%

Other:CO,CH4,etc

The Main Reaction

| The Main Reaction: | |

| CH3OH=CO+2H2 | -90.7KJ/mol |

| CO+H2O=CO2+H2 | +41.2KJ/mol |

| Total reaction: | |

| CH3OH+ H2O=CO+3H2 | -49.5KJ/mol |

| side reaction: | |

| 2CH3OH=CH3OCH3+H2O | +24.9KJ/mol |

| CO+3H2=CH4+H2O | +206.3KJ/mol |

Product characteristics of hydrogen production plant by methanol cracking

H2:75% CO2:≤5ppm CO:≤5ppm purity:99.9-99.9999%

Product characteristics of hydrogen production plant by methanol cracking

1.Methanol cracking hydrogen production is the core product of LABOO with reasonable structure, 10% lower energy consumption than similar products.

2.The operation of the device is stable and can keep running all year round.

3.The device occupies a small area with reasonable arrangement, and is the smallest in the same kind of equipment in China.

4.High level of automation which realized unattended management on site

5.The device can adjust the load freely and safely under the condition of 30-110 flow rate.

6.PSA hydrogen outlet pressure can be up to 2.5MPA without pressurization, if you need higher pressure, we can provide you with booster solution, up to 15Mpa.

7.According to your site situation, we can make the system into steel structure, concrete structure, container structure, semi-closed structure, turnkey engineering for whole system.

8.By 2015, the largest methanol hydrogen production plant designed by LABOO was 20000Nm3/h

Schematic diagram of process for hydrogen production by methanol cracking